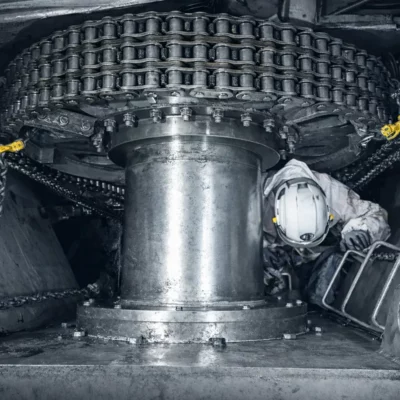

Engineering for your industrial projects

We support industrial clients by offering a comprehensive range of services including design, machining, assembling and on-site integration, covering all aspects from technical requirements to turnkey solutions.

1

Qualified process

Validated, documented processes updated according to client and sector requirements.

2

Inspection

Checks at every stage of production, from supply to final testing.

3

Traceability

Material tracking, data recording, management of non-conformities, and corrective actions.

4

Continuous improvement

Analysis of feedback, quality management, and ongoing optimization of practices.

Lifting capacity

20

tons, for large parts handled safely

production hours

54887

hours completed in 2025 across the two production sites

Collaborators

80

in close collaboration with the other Business Units of the group

Location

2

Mallevialle and Quatre Vents sites, located in Verneuil-sur-Vienne (87)

Recruitment

See all